OntecJetAir is Ontec’s electronic aviation fuel quality management system used in airports since 2008. The system is compatible with JIG Standard, according to which aviation fuels are handled. Ontec had an opportunity to talk with JIG’s General Manager Mark Newstead about the JIG Standard and the very important organisation behind it.

Joint Inspection Group (abbreviated JIG) improves operational excellence and safety in aviation fuel handling operations worldwide by producing world-leading standards. These standards have a big role in keeping aviation safe regardless of the country an aircraft refuels in. In over a hundred countries, 2,750 aviation fuel related facilities operate under the JIG standards.

In this article, we try to find more about the aviation fuel safety structures and the top professionals who work behind the scenes, dedicated to keeping jet fuel “clear and bright”, a term used to describe the required quality of jet fuel.

In aviation, it is common to use technology with double and sometimes triple backup systems. However, there is no backup system for aviation fuel. “Safety is a key aspect in aviation fuelling because we cannot get it wrong. There are no parking places in the sky. Jet fuel has to be delivered in the right quantities, on schedule and on specification every time,” explains JIG’s General Manager Mark Newstead.

“In a non-Covid world, there would be approximately 25-30,000 fuelling operations conducted by JIG members every day”. This means well over ten million annual fuelling operations. GM Newstead estimates several tens of thousands of professionals work globally in aviation fuel handling from manufacturing to refuelling operations.

Joint Inspection Group standards are working very well – there are few aviation fuel-related accidents. “Whilst maintenance and handling errors do occasionally occur – often in the General Aviation segment”, GM Newstead states “It is very rare to have an incident and almost unheard of to have a problem solely attributable to fuel quality at major airport locations. Due to extensive and constant testing and other safety measures put in place with the JIG standard, potential problems, such as fuel contamination, are being identified and resolved long before they could arrive in a fuelling truck under the plane.”

On average, the journey of aviation fuel from the refinery to the wingtip takes one to two months. During that time the fuel and the equipment used to handle it will be checked, sometimes daily, one way or the other.

“Typically, when you find a potential operations problem you eliminate it with an engineering solution. When you can’t, you train people accordingly, and when incidents still occur you work on the human factors that cause people to forget or ignore their training”, GM Newstead states. “It’s a bit of a simplification but most of our organisations are working on human factors.”

Mark Newstead

Education

- University of Oxford, MA

- University of Surrey Business School, MBA

- Kellogg Executive Education

Career

- General Manager, Joint Inspection Group

- Managing Director, Don& Low Ltd.

- Managing Director, Total Specialities USA

- Director, Specialities, Total Italia Spa

- General Manager, Marketing & Sales, Air Total France

- General Manager, Fina Aviation Petrofina

Hobbies

Travelling and sports. “I have been to over 60 countries for work or leisure. I enjoy discovering the food of these countries. When I am at home I try to keep fit by road cycling and setting myself the occasional sporting challenge.”

The road from Oxford to piloting global aviation safety

Oxford graduate Mark Newstead has “spent 35 years in the oil industry, in sales, refining, operations and general management. I was lucky enough to live and work in five different countries on two continents in that time.” Besides English, Newstead speaks also French and Italian on a native level and has some understanding of two other languages, which has helped in working abroad.

“I was introduced to the aviation sector quite early on in my career. It really is an exciting business and a truly global one. You could say that my work was also my hobby. This is fairly typical of people in our sector of activity. The oil industry tends to have high employee retention rates. People are passionate and committed to what they do.” It seems the same holds true of Mr Newstead himself.

How JIG became JIG

“JIG was started as a co-operation between major oil companies. I actually was lucky enough to work with one of the founding JIG members in the early days of my career in Belgium, ” explains GM Newstead. “The oil companies were starting to work together in Joint Ventures in the 1970s to better manage the huge costs of building infrastructure to serve the booming market and needed a way to agree upon common operating practices. This led to JIG – as you see it today – being established as a limited company open to membership in 2002. And in that time JIG has also evolved from providing a common operating standard to also working on efficiency, safety and training programmes for the inspectors it qualifies.”

JIG has a supervisory body – the JIG Council – that provides oversight and guidance to the organisation. “We have a small central team that coordinates the work of experts – generally member employees – who work in our four subject-matter committees. They produce our Standards and Publications and work on the key topics of the day.”, Mr Newstead reports.

Members

The Joint Inspection Group is a non-profit organisation. “Today we have more than 120 members ranging from multinational and regional oil companies to specialist service providers and entities who operate at a single airport or fuel terminal. We encourage aviation fuel handlers to become JIG members in order to enrol in our airport inspection programme that supports the application of the standards and is recognised by the airline community”, tells GM Newstead.

“Approximately one-third of our members are based in Europe and the second third in Africa/Middle East, with the remaining third coming from the rest of the world. There really are no big white spots on the map anymore, other than North America (that operates under an airline standard) and a handful of countries that still have a National Standard.” Some companies from those countries have joined the Joint Inspection Group and have decided to operate under two Standards, acknowledging the added value JIG gives. “Our regular events and workshops that enable our members to meet and learn about or debate ongoing industry issues are a very important reason for being a member for many.”

JIG standards

Primarily the JIG Standards are for the members, but they also available to any operator wanting to adopt them.

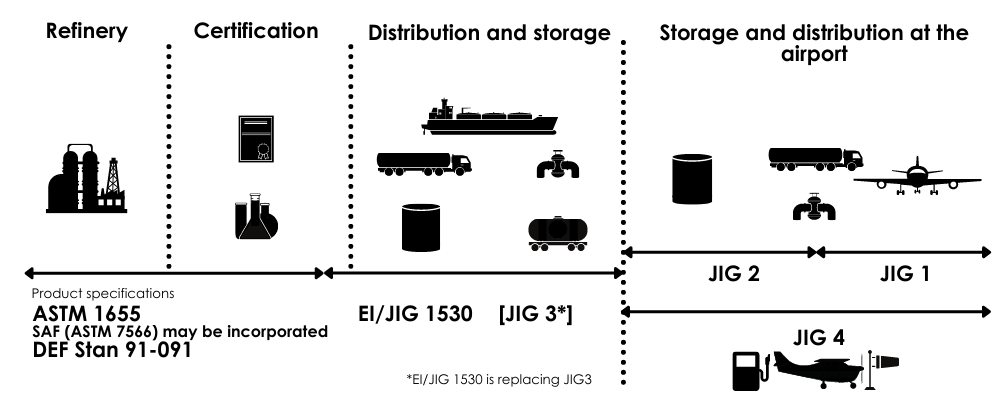

The JIG standards 1, 2 and 4 are updated every five years by the Operations Committee of JIG, which consists of the experts of JIG member organisations (JIG 3 has been replaced by EI/JIG 1530 standard). Updates are needed when the technology changes or the reports from the members’ JIG Inspectors indicate that improvements need to be made. The qualified JIG Inspectors working in the “Inspected to JIG Standards” program gather information systematically to the global JIG database. This helps the members improve their operations and giving JIG some real-time feedback on the effectiveness of the standards.

Concerning cooperation with the authorities, Mr Newstead tells that “regulation is different country by country. We tend not to have so much interaction with authorities that make safety and fuel quality the responsibility of the airline. But we have a lot more to do with those that put that responsibility onto the airport operator. Some national authorities make adoption of the JIG Standard a requirement for a fuel handler to obtain an operating licence and we see this as a growing trend”.

Sustainable Aviation Fuel (SAF)

The aviation industry is deeply concerned about its impact on the environment. The usage of SAF will continue to grow. The different types of Sustainable Fuel blends today are blended into conventional fuels before delivery to airports. “We are already extending our good practices to update users on the best practices in handling and blending SAF”, states GM Newstead “and JIG will keep on working with SAF related subjects that are new to many of our members. The industry is also starting to look at how to extend the service life of equipment through better understanding and better maintenance.”

Rebranding

The Joint Inspection Group is currently undergoing rebranding. A new logo was published some months ago and a new web site has been launched recently. The new site offers more information on the organisation and its tasks in a more user-friendly form. “We are also planning to launch a new service – an eLearning platform for those, who cannot participate in our events on-site. We also have great data resources available for our members”, tells Mr Newstead.

No business like aviation business

Mr Newstead is excited about the future of JIG. As a challenge, he mentions that “Many aviation fuel handling experts are reaching retirement – globally. As an industry, how do we make sure that the tacit knowledge is not lost with those who retire? JIG potentially has a role to play here – we are an aviation refuelling knowledge base, a library, so to speak.”

“JIG is a bit like an extended family. The small team is very active and interacts regularly with members and committee members. We have to say also that the knowledge, commitment and support we get from our Committee members – often on a volunteer basis – is exceptional and the foundation on which JIG’s work is built.”

Keeping us all safe in the skies seems to be at the heart of everything the JIG team, members and GM Newstead do.

This article

was prepared by Ontec Oy, Finland. Ontec Oy is a Known Supplier of Airport Supplies certified by Finavia. Our expertise are aviation fuel (including Jet A-1) quality management software systems (OntecJetAir), also compatible with the JIG Standards. Our customers are aviation fuel operators storing and distributing aviation fuels at airports, including companies such as AirBP and Neste.