OntecMilo is a perfect solution for handling and loading liquids such as fuels, LNG and different chemicals. The system is suited for handling liquid bio-based fuels.

The OntecMilo software operates as a stand-alone system or combined with customers’ existing systems, from cargo planning to MID approved fiscal billing (fuel taxation,custody transfer). Developed for liquid handling management, the MiloEx touch screen can be placed in the ATEX area. The technology of the product is protected from manipulation in a MID-approved manner and the audit trail guarantees the traceability of all necessary transactions.

Fluid loading management with OntecMilo software and MiloEx touch screen

At OntecMilo, cargo planning can be carried out from beginning or the data can be impoted directly from the customer’s own system via interfaces. Similarly, actual cargo and event data can also be transmitted to different systems. Information about cargos and events can be retrieved and browsed using the MID -tag.

MiloEx touch screen

-40…..+60 °C operating environment temperature range

approved ATEX 2(1)G device class requirement

RTA -detection integrated into the display

21,5″ touchscreen display, FullHD

IP66-rating

dustproof

OntecMilo software includes:

- real-time control and monitoring of cargos,

- management of vehicles and transport company´s information,

- data updates and compartment configuration,

- management of customer-specific products and recipes,

- maintaining customer information, such as contact and billing information,

- tax information, as well as tracking the customer’s inventory balances.

OntecMilo is the perfect solution for working with liquids.

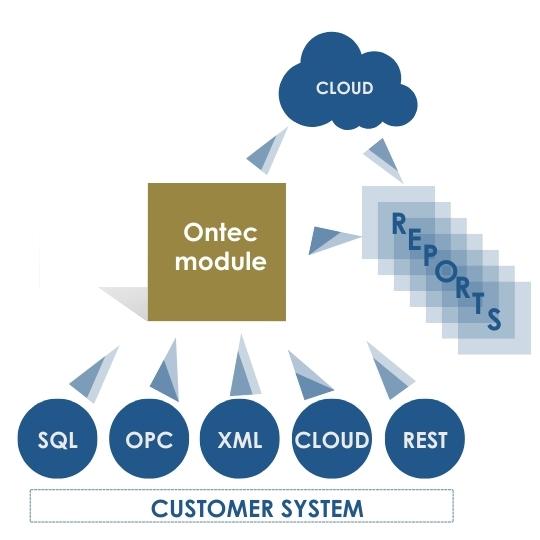

Ontec data integration possibilities

Ontec product modules are easy to integrate to any system available. Data transmission possibilities are for example: SQL, OPC, XML, Cloud and REST -interface for http request. OntecMilo system can be used cloud based – work anywhere and with any mobile device. Reports are easy to generate directly from OntecRTM or via cloud solutions.

Increasing role of software in measurements

Digital measuring and storing of data is constantly developing. MID pays special attention to securing software and protecting it from corruption.

According to MID, components that are critical for metrological characteristics have to be designed so that they can be secured. Even attempted intervention should be registered and evidence of it has to be available for a reasonable period of time. Measurement data, software that is critical for measurement characteristics and metrologically important parameters stored or transmitted must be adequately protected against accidental or intentional corruption. It should not be possible to reset utility measuring instruments displaying total quantity supplied, when this amount is used for invoicing.

All these requirements have been taken into consideration in the development of OnatexMID measurement system.